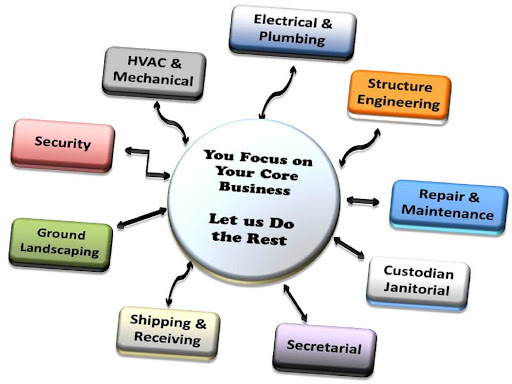

You cannot have a sound asset management system without having a solid maintenance strategy. Assets work best only when they are serviced well and on time. Regular inspection of assets can solve the biggest problem of any company- i.e. downtime. In the past a lot of industrial units have shut down their processes due to heavy operational losses; only with the help of skilled and technologically advanced maintenance team, a unit can perform optimally without incurring unnecessary costs. Another crucial role of a maintenance manager is to manage the MRO parts efficiently.

What is MRO?

MRO refers to the Maintenance, Repair and Operational aspects of any unit. These comprise all the materials, equipment and supplies used in the production process. Although it is impossible to produce finished goods without the MRO items, they are n seen in the finished goods.

MRO items include:

- Repair tools and supplies

- Gloves

- Safety tools

- IT infrastructures like laptops and computers

- Stationery items

- Cleaning and Laboratory running items

Managing a production unit is a very challenging task; with the help of a technologically empowered preventive maintenance strategy, the maintenance department can improve the overall performance and safety standards of the unit and reduce cost and downtime considerably.

Let's look at five tips for efficient preventive maintenance.

-

Get a strong plan

Preventive maintenance cannot be achieved without detailed and proper planning. Every piece of asset under the unit must be mentioned in the plan. This plan will work will consist of the maintenance schedule of every asset, thus working as a blueprint for all the technicians. This procedure will not only keep our equipment’s healthy and running but will also help managers to controls repair costs and expand the lifespan of pieces of equipment.

-

Identify the small repetitive problems

Before a problem becomes big, identify it, and solve it immediately. If the entire maintenance team focuses on addressing small issues related to assets and equipment’s in the initial stages, big problems can be avoided.

-

Know the difference between work time and idle time

One maintenance plan for all assets will not be a practical decision, an asset that has 20% idle time will need frequent preventive maintenance compared to a machine that has only 5% idle time.

Idle time is referred to the time that is costing the company in terms of cost of labour or machine; however, in those productive hours due to various factors like machine breakdown, strikes, power cut and many others. By minimising idle time, the work time can be optimally used productively.

-

Anticipate the needs

Inventory management is a critical part of maintenance management. Surplus inventory can lead to wastage, while inadequate inventory can lead to equipment idle time. Thus, to manage inventory, you need a CMMS based asset management software that can record the exact status of inventory in real-time and help inventory managers to make informed and calculated decisions.

-

Data is important

The role of data is crucial for every business. Thus, as maintenance managers, you take the help of a CMMS. CMMS records every small data related to every asset, right from the time the asset was purchased. The warranty period, repair history, performance report and many others are recorded in the CMMS. With such reliable data, you can make the right decisions. Based on this data, you can prepare your preventive maintenance schedule.

The Bottom Line:

You can achieve the gold standards of maintenance if you religiously follow the above tips. Begin by auditing your system and identifying the small and big issues. Next, adopt the CMMS with the right features that suites your business and train your people to use the power of technology to improve your processes.